Had one last brass piece to make for each boat, though I’m not sure what to call it. Rudder Shoe? Rudder Slipper? Basically, it’s a Rudder “Weed/Crab Pot/Eel Grass/Sawgrass/Gunk Preventer” based on a brilliant idea from Roger Rodibaugh, Grand Poobah of the Crawford Melonheads.

All rudders pick up junk floating in the water, but raked rudders are especially bad. They’re like a finger sticking down in the water, scooping up everything in their path. In open water it’s not usually a big deal. But where I do most of my sailing – near shore, shallow water, marshes, etc. – it can be a real problem. Here on the Chesapeake, crab pots are everywhere, and if you don’t keep an eye out for them you slip right over the floats, and the line that connects them to the pot slips right into the slot between the rudder and the skeg. Not fun. If you sail through a marsh, the same slot will fill up with sawgrass, cattails, lily pads, and other assorted flotsam. Usually it’s just annoying. You just lean over the stern and pull it out. There are times, though, when it may not be a good time to do that, and in rare situations unexpected crud can even lift a rudder out of it’s gudgeons and set it free. Even bumping over a sandbar can do that. I speak with the voice of experience here, on all counts. Something similar happened to Russ Manheimer on Sjogin, and he’s still looking for his rudder, I think.

Something similar happened to Russ Manheimer on Sjogin, and he’s still looking for his rudder, I think.

To prevent such mishaps, Roger Crawford adds a small brass piece of bent half oval to the transom that pivots on a screw and keeps the rudder in place. You can buy stainless steel spring clips that serve the same purpose. This doesn’t help with the weed problem, though. Roger Rodibaugh sails mostly in freshwater lakes, and his boat is often seen floating in a sea of lily pads. To solve the weed gathering problem, he attaches a little plastic cone-shaped flap to the bottom of his skeg that overlaps the leading edge of the rudder. This keeps the tip from scooping up the crud. I haven’t seen it, but he has described it. It’s rather ingenious for both simplicity and effectiveness, and the idea has always stuck with me. To make something a bit more permanent, I decided to do the same thing in brass, which made it neither simple nor easy, but it’s done.

One good thing came out of it, though. I learned that Citric Acid, which can be bought cheaply in bulk from health food stores, is excellent for cleaning brass and bronze. If only I had done a little more Googling, Terri and I wouldn’t have spent a whole day cleaning off soot and flux from the first pieces of hardware. A few minutes in the Citric Acid bath and the stuff just wipes off; a little rubbing with 0000 steel wool takes off a thin skin of redeposited copper and you’re back to shiny metal. In fact, this “pickling” in the acid is done before brazing to clean the metal for a good bond, and after to clean it up. It also “pacifies” the metal, making it less reactive, so it doesn’t tarnish as quickly. Sweet. I had some Citric Acid on hand already, because I used it to restore the old chisels and planes I inherited. A teaspoon in a quart of warm water did the trick.

I don’t have any photos of the finished Preventers before they were installed (I was pretty irritated by that point. Did you know that soft brass gets stiffer every time you bend it? Well, it does. Really.), but here are some from the start and the finish:

Citric Acid Test before

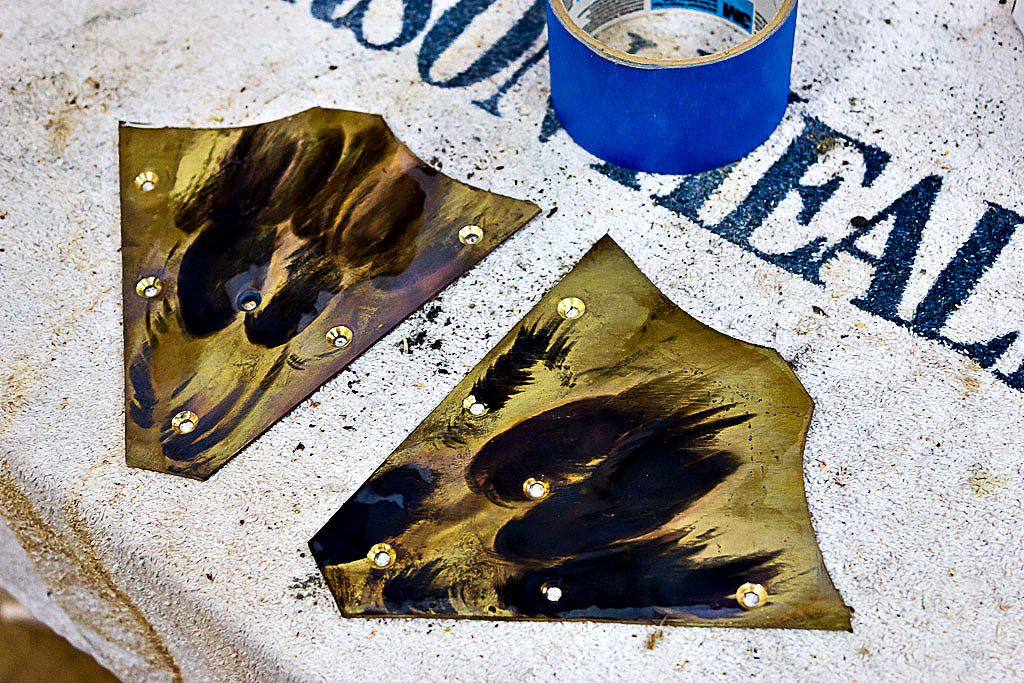

Brass plates drilled and ready

Brass plates drilled and ready

After a quick swish in Citric Acid bath, the soot comes off with a soft brush.

After a quick swish in Citric Acid bath, the soot comes off with a soft brush.

The Copper deposits left behind rub off with steel wool.

Finished Shoe on Aeon. Cleaned, bent, hammered and installed.

Finished Shoe on Aeon. Cleaned, bent, hammered and installed.

These pieces look nice, but were not easy to make, and will no doubt increase drag a bit. When these get loose or beat up, I’ll likely replace them with just a rubber flap screwed down with flat brass straps. Much easier to make, flexible, and less drag, too, if not as pretty.

melonseed skiff, mellonseed skiff, melon seed, mellon seed

hi,

i was just wondering how much citric acid you used in the solution?

thanks

Hi Steffany, there’s no critical formula. You can use a lot or a little. I’m usually working quickly, with large dirty pieces, so prefer a strong mix. I start with hot water to dissolve a couple of heaping spoonfuls of powder in a bowl of water. Roughly a teaspoon to the cup.

Dangit! Learned something else from Barry….. Citric Acid – who’da thunk it? I’ve got a brass bell from a 1956 Santa Fe Locomotive (don’t ask where I got it) thats had lots of elbow grease used to polish it over the years, now I have to go to the health food store!

https://www.facebook.com/photo.php?fbid=709813309065639&set=pb.100001109304396.-2207520000..&type=3&theater

😉