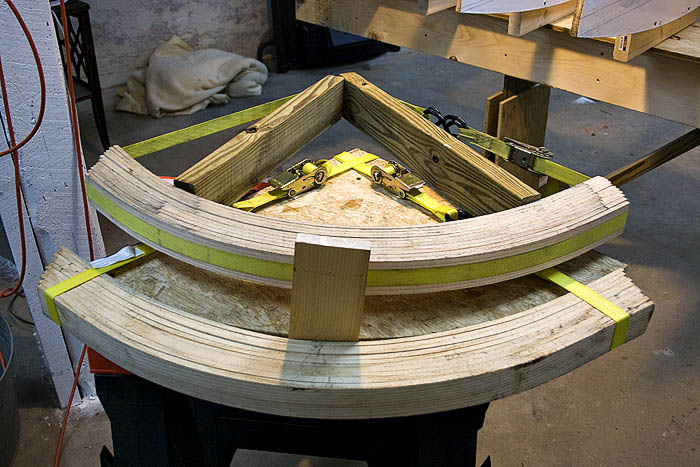

Epoxied stem laminations

The strips are laminated together with thickened epoxy. Barto suggests laminating the entire stem together in once piece, then cutting the whole thing apart to form the inner and outer stem portions. As Tony Thatcher pointed out to me, that task is much easier if you have a band saw handy, which I don’t. Instead, I applied tape to the strips between one of the laminations to protect them, and skipped that layer when spreading the epoxy. Once the epoxy cured, a putty knife separated the two sections. They can be trimmed and shaped separately when the time comes. Doing it this way will make a couple of tasks easier down the road.