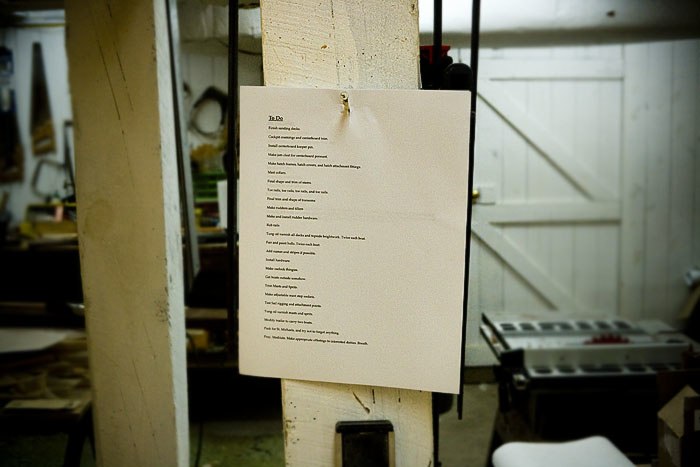

The “To Do” List

There are now a pair of lists posted in the shop. Though the order on them is somewhat arbitrary, they will govern activities for the next three weeks. The first one is a bit daunting:

To Do

- Finish sanding decks.

- Cockpit coamings and centerboard case trim.

- Install centerboard keeper pin.

- Make jam cleat for each centerboard pennant.

- Make hatch frames, hatch covers, and hatch attachment fittings.

- Mast collars.

- Final shape and trim of stems.

- Toe rails, toe rails, toe rails, and toe rails.

- Final trim and shape of transoms

- Make rudders and tillers

- Make and install rudder hardware.

- Rub rails

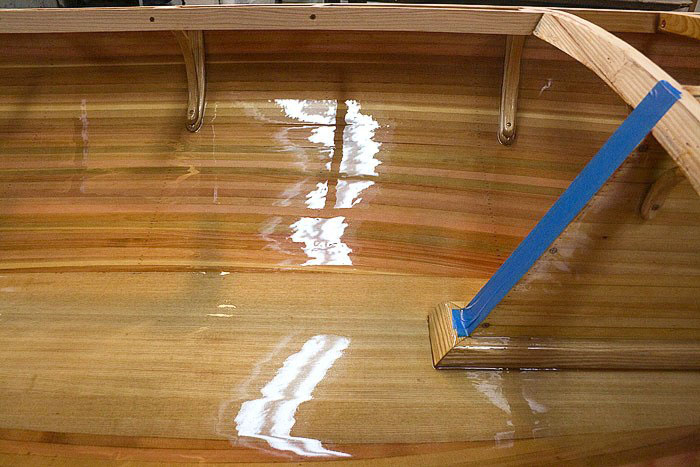

- Tung oil varnish all decks and topside brightwork. Twice each boat.

- Fair and paint hulls. Twice each boat.

- Add names and stripes if possible.

- Install hardware.

- Make oarlock thingies.

- Get boats outside somehow.

- Trim Masts and Sprits.

- Test Sail rigging and make attachment points.

- Make adjustable mast step sockets.

- Tung oil varnish masts and sprits.

- Modify trailer to carry two boats.

- Pack for St. Michaels, and try not to forget anything.

- Pray. Meditate. Make appropriate offerings to interested deities.

- Breathe.

To Do Later

- Varnish undersides of decks.

- Add two more varnish coats everywhere else.

- Add another coat of paint.

- Add Brass Stem Band and rub strip along keel.

- Install drain plug.

- Make floorboard decks.

- Make canvas spray shield.

- Sail often.

Most of these things are simple and straightforward. Some, like the toe rails, are a little tricky and complicated, made only more so by the fact they’ll be so prominently displayed. A few things from the first list could be demoted to the second, but not many if we actually want to go sailing in St. Micheals this year. I’ll have to complete at least one item a day, and several on the weekends, to be done by the first weekend in October. If it turns out sailing is not an option, then heck, we’ll go rowing. Modus Operandi is attack the first list at the beginning, start chewing down through it, and see how far we get. Adapt as necessary.

It’s easy to get caught up in a race mentality, which would probably be a mistake. I have to keep remembering the ultimate goal of the last 20 months of work is not to make a big splash on one weekend. It’s to have two boats I’m happy with, proud of, that I’ll be sailing for at least the next 30 years. I could easily botch something trying to hurry, and then have to live with it for 30 years, which would kinda suck. And, I expect to go back to MASCF every year for years to come, not just this year. This is not to say I’m conceding defeat, just graciously accepting whatever comes.

With all that in mind, North got its Deck flush cut and sanded earlier in the week. This morning it got a pretty Walnut Transom. This afternoon, a deck gets sanded and work begins on Cockpit Coamings.

melonseed skiff, mellonseed skiff, melon seed, mellon seed